Global Specialists in Technical Ship Removal & Marine Recovery

Wreck salvage – when everything else fails

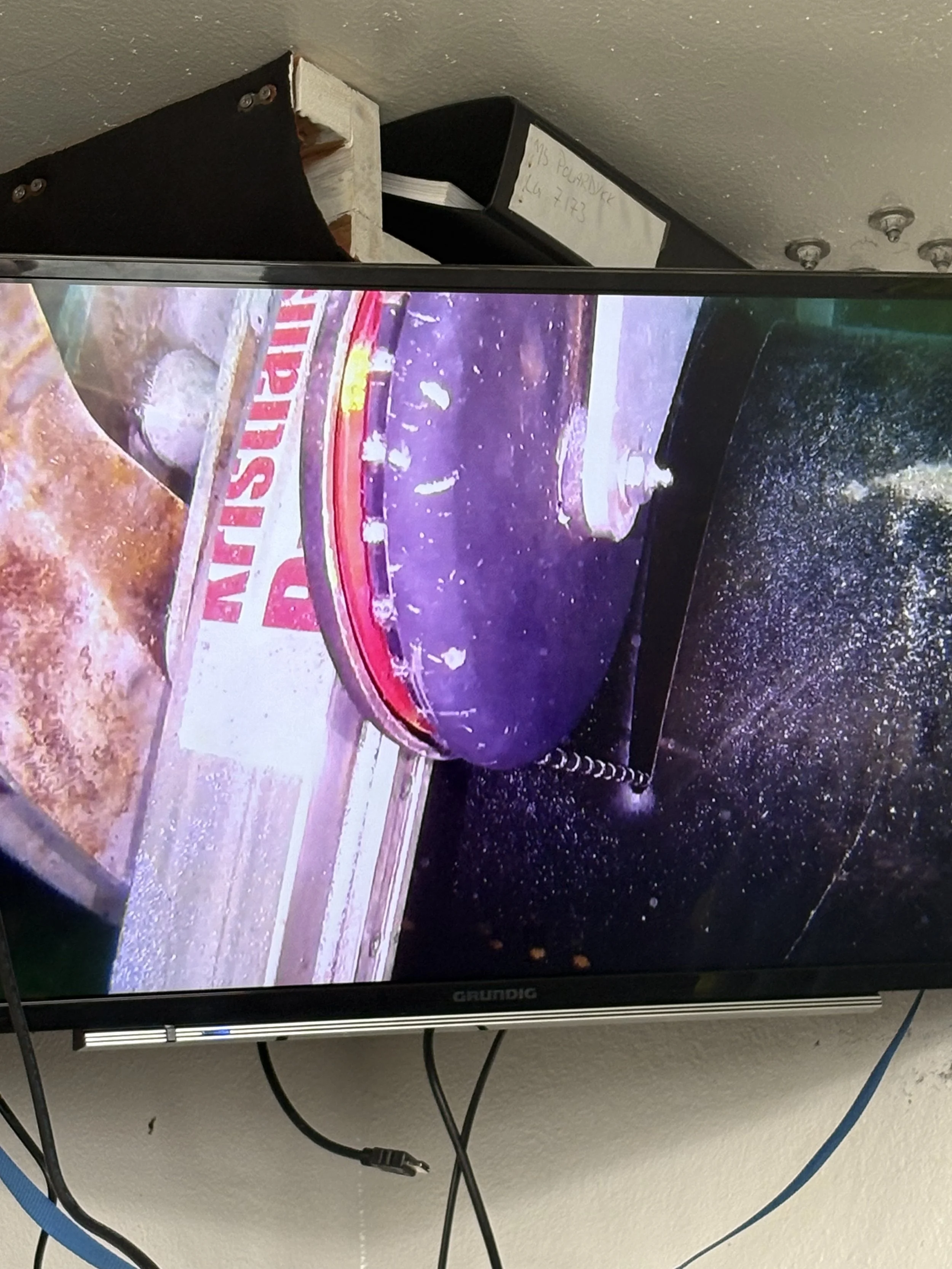

Precision Recovery: Kristiansand Bygg performing a 400-tonne ship section lift after successful subsea diamond wire sawing. This demonstrates our capability for large-scale, engineered salvage operations.

The Last Resort for Complex Marine Recovery

When a vessel runs aground in extreme weather or treacherous conditions, conventional salvage methods often reach a breaking point. When the risk of structural collapse or environmental catastrophe becomes too high for standard towing and refloating — that is when Kristiansand Bygg is called in.

We specialize in the surgical dismantling of wrecks that have been deemed "un-salvageable" by others.

Where conventional salvage reaches its limit, our Diamond Wire Cutting solution provides a controlled, surgical approach for the precision dismantling of some of the world’s most complex and demanding shipwrecks.

Technical Wreck Removal & Subsea Sectioning:

How we do wreck-salvage?

Final Sectioning of MS Osfjord: Cutting Through the Main Engine Here we conclude the diamond wire sawing by cutting through the main deck of MS Osfjord. In this single, continuous cut, we successfully sectioned the ship's entire main engine. This operation demonstrates the extreme power of our subsea wire system, capable of slicing through the most massive internal components of a vessel to ensure complete dismantling.

When insurance companies and authorities determine that regular salvage is no longer feasible, Kristiansand Bygg provides a definitive, engineered solution. Together with our strategic partners, we specialize in the complete removal of shipwrecks by systematic dismantling. Our approach is designed to eliminate the risks associated with traditional heavy-lift operations, such as structural collapse or massive pollutant release.

The Process: Surgical Precision Below the Surface

Successful Recovery of the Stern Section Following the completion of the initial diamond wire cut, the stern section is successfully recovered. Weighing close to 60 tonnes, this lift marks the first major milestone in the systematic dismantling process, demonstrating the precision of our subsea sectioning strategy.

Environmental Containment: Before any cutting begins, we establish physical barriers and continuous subsea monitoring. This ensures that any potential spills are contained and the surrounding marine environment is fully protected throughout the operation.

Surgical Dismantling: Using our proprietary Diamond Wire system, we section the wreck into manageable pieces. By cutting from the seabed up, we maintain total control over the structural integrity and weight distribution of each section.

Systematic Recovery: Each section is carefully lifted and transported to a certified yard for final dismantling and recycling, ensuring a 100% clean seabed.

Precision Recovery: Lifting a 400-Tonne Section After completing the subsea diamond wire cut, this 400-tonne section is successfully recovered from a depth of 20 meters. Our meticulous planning and structural calculations ensure that even the heaviest sections are dismantled and lifted with total control, providing a safe and efficient conclusion to the ship removal process.

Our Method :

Engineering & Pre-Project Planning Every shipwreck removal starts in our engineering department. We perform structural analysis and 3D-modeling of the cut-sequence to ensure the vessel remains stable throughout the process. Our team calculates the weight and center of gravity for every section to ensure safe lifting operations by crane barges or transport ships.

High-Performance Subsea Cutting This image demonstrates our diamond wire cutting through the hull with exceptional efficiency. Operating at a cutting speed of 18 meters per second, our specialized system ensures rapid and precise sectioning of the vessel, significantly reducing operational time on the seabed.

Technical Capabilities of our Subsea Diamond Wire System:

Precision Cutting: Capable of cutting through multi-string casings, reinforced concrete structures, and heavy-grade steel alloys.

Any Depth: Engineered for deployment at various depths, from shallow harbour operations to deep-sea recovery.

Custom Rigging: We design and fabricate bespoke guide frames and clamping systems to fit the unique geometry of every wreck or subsea asset.

Cold Cutting: Our diamond wire method is a "cold cutting" process, eliminating the risk of fire or explosions in vessels containing fuel or hazardous materials.

Subsea Precision under Extreme Tension This image clearly shows the immense structural forces at play. At a depth of 8 meters, the steel began to deflect as the internal tensions were released during the cut. Operating under such extreme pressure requires our specialized wire saws and expert control to ensure a safe and successful detachment.

Our Experience: Craftsmen at Depth

Kristiansand Bygg is a specialized contractor in wire cutting, core drilling, and subsea engineering.

A core pillar of our success is our personnel strategy: We don’t use divers who can practice crafts; we employ master craftsmen who are certified to dive. This distinction ensures that high-quality industrial work is delivered even under the most demanding underwater conditions.

Vessel Salvage: Large-scale ship removal using diamond wire technology.

Asset Recovery: Salvage of construction machinery, vehicles, and industrial equipment from the seabed.

Global Reach: While located in Kristiansand, Norway, we draw on our experience from the harsh Norwegian coastline to deliver services to most locations worldwide.

Our Specialized Subsea Services:

Wreck Removal & Dismantling: Surgical sectioning of grounded or sunken vessels.

Subsea Decommissioning: Removal of offshore structures, pipelines, and templates.

Infrastructure Repair: Precision cutting for bridge pillars, dams, and harbour installations.

Asset Recovery: Locating and retrieving lost high-value industrial equipment.

Emergency Response: 24/7 mobilization for urgent maritime threats.

Precision Subsea Recovery: Pile Driver Detachment At a depth of 8 meters, our team deployed one of our custom-built subsea wire saws to precisely detach a submerged pile driver. By utilizing our proprietary specialized equipment, we ensured a controlled and surgical separation, facilitating a successful recovery of the heavy industrial asset.

Emergency Response & Technical Consultation

Available 24/7 – Rapid Mobilization Worldwide

Technical Lead / Duty Officer: > +47 902 03 797

Click to call for immediate assistance

Engineering & Project Inquiries: post@kristiansandbygg.no

Global Headquarters: Vigeveien 15a, N-4633 Kristiansand, Norway

Strategic location for North Sea and international mobilization.